Finishing the surface of the wood can be either the last step of your woodwork project or your regular maintenance for your wooden furniture, floors, windows, and doors.

Oils are among the most common wood finishes and have been used for centuries in almost all parts of the world. Oils are basically a natural product, although, nowadays, there are several chemical additives to enhance their protective effect and to make the application easier. While varnish, shellac polyurethane or lacquer might perform better in some areas, many people still prefer treating their wooden furniture with oil.

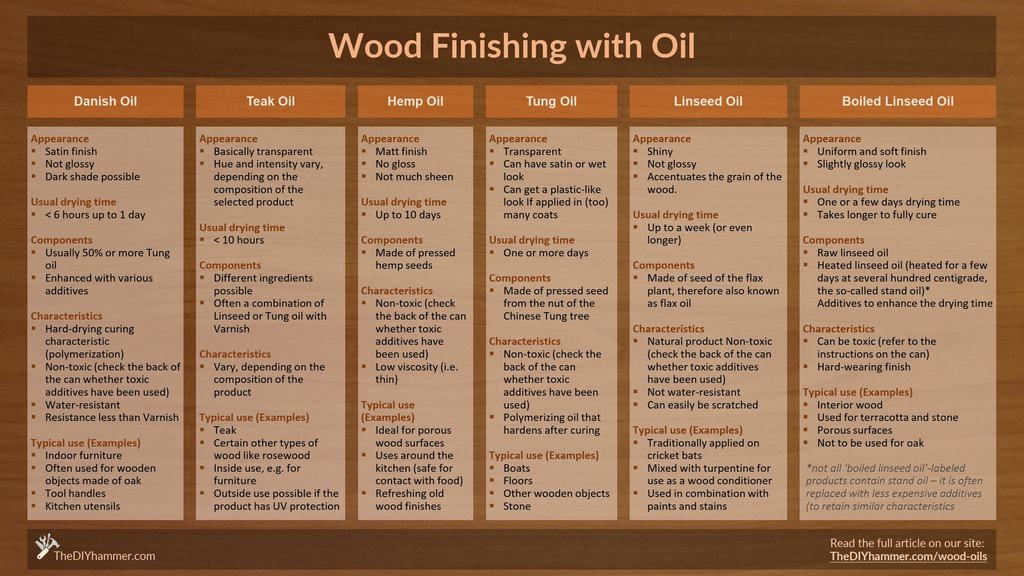

In this article, we are introducing the most popular wood oils – Danish oil, Teak oil, Hemp oil, Tung oil, Linseed, and Boiled Linseed oil – with their respective characteristics. You will also find links to more detailed posts about some of the oils. For a quick overview, you can look at our comparison table.

Before you start working with wood oils, you should get your safety equipment ready, i.e. goggles, gloves, and a mask, in particular for the application of synthetic oils. Use our wood oil calculator to find out how much oil you need for your project.

Danish Oil

Check and compare Danish oil on Amazon.

In a Nutshell:

Appearance

- Satin finish

- Not glossy

- Dark shade possible

Usual drying time

< 6 hours up to 1 day

Characteristics

- Hard-drying curing characteristic (polymerization)

- Non-toxic and food-safe (check the back of the can whether toxic additives have been used)

- Water-resistant

- Resistance less than Varnish

Components

- Usually 50% or more Tung oil

- Enhanced with various additives

Typical use (Examples)

- Indoor furniture

- Often used for wooden objects made of oak

- Tool handles

- Kitchen utensils

Price

Check prices of Danish oil on Amazon.

Danish oil is a rather matt finish for wood. It is usually a mix consisting of at least 50% Tung oil supplemented with additives that enhance its performance. Its name stems from the popularity of Scandinavian furniture all over the world for which this oil can be used.

Danish oil is easy to apply and fast drying – it may take even less than 6 hours to dry, depending on the conditions. It is non-toxic and water-resistant. Usually, it does not affect the natural appearance of wood (although it might add a slight color shade to it). However, this finish is not as tough and as resistant as varnish.

Read more in our article “Danish vs Tung oil”

How Does a Finish with Danish Oil Look Like?

Danish oil adds a matt or satin finish to the wooden surface. It is not glossy but can come with a dark shade. As Danish oil is a mixture of other generic oils and additives, the appearance will vary among the different brands. Therefore, it is important to test it on an invisible place of the wood before applying it to the entire work piece, so you can check whether you are willing to accept the hue.

How Long Does Danish Oil Take to Dry?

Danish oil has a drying time that varies from less than 6 hours up to 1 day, depending on the product used and the individual circumstances. This oil is a hard-drying oil (undergoing a polymerization).

How to Apply Danish Oil

Time needed: 3 days

How to Apply Danish Oil: These steps refer to a comprehensive method for applying Danish oil. However, there is also a shorter common method of how to apply Danish oil. That method takes only a day and is suitable for smaller pieces while the one presented here is ideal for larger pieces, provides a more thorough treatment but takes several days. Read our dedicated post “How to Apply Danish Oil” incl. step-by-step guidance for the shorter method.

- Sanding

Sand the surface and remove any existing previous finish.

- Application of the first coat of Danish oil

Apply the first coat of Danish oil. Afterward, remove any excess after application. - Drying

Let the coat fully cure (it can take from 6 hours to 1 day).

- Second round of sanding

Sand with fine-grit sandpaper, if necessary or desired. Otherwise, skip this step.

- Application of a second and more coats

Repeat steps 3 and 4 until you achieve the desired smoothness of the finish (often 2-5 coats while some DIYers argue that, at some point, the sanding can be skipped).

What Is Danish Oil Used for?

Danish oil is usually non-toxic (you want to check the back of the can whether other additives have been used though) and somewhat water-resistant. Thus, it is not only used for indoor furniture – in particular furniture made of oak wood – but also for tool handles and wooden kitchen utensils.

Like most, if not all oils, it is not as resilient and durable as varnish.

Teak Oil

Check prices for Teak oil on Amazon now.

In a Nutshell:

Appearance

- Basically transparent

- Hue and intensity vary, depending on the composition of the selected product

Usual drying time

< 10 hours

Characteristics

- Vary, depending on the composition of the product

Components

- Different ingredients possible

- Often a combination of Linseed or Tung oil with Varnish

Typical use (Examples)

- Teak

- Certain other types of wood like rosewood

- Inside use, e.g. for furniture

- Outside use possible if the product has UV protection

Price

Check prices for Teak oil on Amazon.

You might have seen Teak oils in your DIY store or even used it yourself for your Teak furniture. However, this label is mainly a marketing thing – there is no such thing as a natural Teak oil, actually (you will find an insightful analysis of that topic on Popoularwoodworking).

What stores sell as teak oil is usually a mix of linseed or Tung oil and varnish. However, its composition can vary.

Read more in our article “Teak oil vs. Tung oil” where we compare these popular oils.

How Does a Finish with Teak Oil Look Like?

Teak oil is supposed to protect and enhance the natural color and grain of Teak wood. However, it may vary whether and which shade it adds. This depends on the composition of the selected product.

How Long Does Teak Oil Take to Dry?

Teak oil is rather fast drying. It usually takes less than 10 hours, depending on the mix of the product and the circumstances.

How to Apply Teak Oil

You can apply Teak oil with a brush or a rag, following these steps:

- Preparation

Sand the wood with a fine grit sandpaper. - Application of the first coat of Teak oil

Apply the oil by wiping it into the grain with movements in direction of the grain. Let it soak in. - Application of more coats of Teak oil

After a few minutes, you can apply more Teak oil. - Wipe the surface

After another few minutes, you should wipe the surface before letting it dry for up to 10 hours. - Application of more coats of Teak oil

If desired, you can apply a third or fourth coat of Teak oil, following the steps 2 and 3. - Final sanding

At the end, Sand or polish the work piece with fine-grit sandpaper (e.g. 220) or steel wool.

What Are the Typical Uses of Teak Oil?

Teak oil is used for certain types of wood like rosewood and – obviously – Teak. It can be used for furniture – even outside the house if the selected product offers UV protection.

Hemp Oil

Compare Hemp Oils & check current prices on Amazon.

In a Nutshell:

Appearance

- Matt finish

- No gloss

- Not much sheen

Usual drying time

Up to 10 days

Characteristics

- Non-toxic (check the back of the can whether toxic additives have been used)

- Low viscosity (i.e. thin)

Components

- Made of pressed hemp seeds

Typical use (Examples)

- Ideal for porous wood surfaces

- Uses around the kitchen (safe for contact with food)

- Refreshing old wood finishes

Price

Check current prices on Amazon.

As the name suggests, Hemp oil is made of pressed hemp seeds. It leads to a gloss– and sheen-free matt appearance. As a natural and non-toxic oil, it can also be used around the kitchen.

Hemp oil has a low viscosity (i.e. it is comparatively thin) and therefore does not require any thinning before its application.

You will find more details in our dedicated article on Hemp oil where we discuss more aspects.

How Does a Finish with Hemp Oil Look Like?

Hemp oil gives wooden surfaces a matt finish without gloss. It also does not create much sheen.

How Long Does Hemp Oil Take to Dry?

Being a natural product, it takes Hemp oil a long time to fully dry – up to 10 days or even more under adverse conditions.

How to Apply Hemp Oil

You can apply Hemp Oil with a brush or a cloth on a sanded or painted work piece. Let it soak in and wipe off the excess after a couple of hours. Repeat this process and let it dry for 10 days or more.

Note that natural hemp oil is green. No worries though: this will not give the wooden surface a greenish hue at all.

What Is Hemp Oil Used for?

Thanks to its low viscosity, Hemp oil is ideal for porous wood surfaces. It is mainly applied when refreshing old finishes on wooden pieces or as a final layer over dried paint.

As natural Hemp oil is non-toxic and safe for contact with food, you can also use it around the kitchen.

Tung Oil

Find Tung Oil and compare prices on Amazon.

In a Nutshell:

Appearance

- Transparent

- Can have a satin or wet look

- Can get a plastic-like look If applied in (too) many coats

Usual drying time

One or more days

Characteristics

- Non-toxic and generally food-safe (check the back of the can whether toxic additives have been used)

- Polymerizing oil that hardens after curing

Components

Made of pressed seed from the nut of the Chinese Tung tree

Typical use (Examples)

- Boats

- Floors

- Other wooden objects

- Stone

- Kitchen

Price

Check current prices on Amazon.

Tung oil is made of pressed seed from the nut of the Chinese Tung tree (source). It is usually transparent and non-toxic and can even be used for toys made of wood (check the back of the can whether toxic additives have been used). Tung oil is also water-resistant.

Read more in our articles “Danish vs Tung oil” and “Teak oil vs Tung oil”.

How Does a Finish with Tung Oil Look Like?

Tung oil produces a transparent finish. In some cases, it can have a satin or a wet look.

You can achieve – or avoid – a plastic-like look of the finished surface, which tends to occur upon applying (too) many coats of Tung oil.

How Long Does Tung Oil Take to Dry?

The drying time is one or more days upon applying Tung oil. It is a polymerizing oil that hardens after curing.

How to Apply Tung Oil

- Sanding

Prepare the (re)finishing of the wood by sanding the surface with fine-grit paper. - Preparation

Consider thinning some portion of your Tung oil to fill pores of the wood. - Applying the Tung oil

Apply the Tung oil with a brush or cloth and remove the excess oil after a few hours. Let the applied oil dry for at least 24 hours. - Sanding and applying more coats of Tung oil

Consider sanding the wood after the first coat has dried. Apply another coat of Tung oil, let it dry, and apply more coats as often as needed. - Sanding

Sand the surface with fine sandpaper and/or steel wool before you apply the final coat of Tung oil. - Final layer of Tung oil

Apply the final coat of Tung oil and allow it to dry for a couple of days. - Final Sanding or Polishing

Sand or polish the surface with very fine sandpaper (> 220) and/or steel wool.

What Are the Typical Uses of Tung Oil?

One of the most common uses of Tung oil relate to wooden surfaces of boats. It is also popular for wooden bridges, decks, sheds and other wooden installations that are near the water.

You can use Tung oil for floors, other wooden objects and stone as well.

Linseed Oil

Compare Linseed oils and prices on Amazon.

In a Nutshell:

Appearance

- Shiny

- Not glossy

- Accentuates the grain of the wood

Usual drying time

Up to a week (or even longer)

Characteristics

- Natural product Non-toxic (check the back of the can whether toxic additives have been used)

- Not water-resistant

- Can easily be scratched

Components

Made of the seed of the flax plant, therefore also known as flax oil

Typical use (Examples)

- Traditionally applied on cricket bats

- Mixed with turpentine for use as a wood conditioner

- Used in combination with paints and stains

Price

Check current Linseed oil prices on Amazon

Linseed oil is a natural oil. It is produced from the seed of the flax plant and therefore also referred to as flax oil. It is a natural product that is non-toxic. However, off-the-shelf Linseed oils can contain additives, so check the back of the can if you intend to use it around the kitchen.

Its application is time-consuming though: you will have to apply several coats and each coat takes a couple of days to dry.

You might not want to use Linseed oils outdoors as they are not very weather-resistant. It also does not offer much resilience to rough contact or wear and it can easily be scratched.

How Does a Finish with Linseed Oil Look Like?

This oil accentuates the grain of the wood and enhances its natural color. Linseed-treated wood has a shiny look while it is usually not glossy.

How Long Does Linseed Oil Take to Dry?

Linseed oil dries very slow – it can take up to a week or more until it has dried. The long drying time is indeed one of the most important disadvantages. If you plan to work with linseed oil, you should take into consideration that it requires 2 to 3 days drying time between coats – so, applying Linseed oil extends over at least 1 or 2 weeks.

How to Apply Linseed Oil

- Sanding

Sand the surface first, using a fine-grit sand paper, before you apply the hemp oil. - Preparation of the hemp oil

You can prepare the hemp oil by boiling it shortly and thinning it by mixing it with turpentine (e.g. with a ratio 3:1 to 5:1, depending on the use). - Application of the hemp oil

Apply the oil with a brush, roller or cloth. After 20 to 40 minutes, remove any excess oil. - Application of more coats

Repeat the procedure after 2 to 3 days, and apply more coats if necessary. - Final sanding

Consider sanding or polishing the surface with fine sandpaper (> 220) or steel wool.

What Is Linseed Oil Used for?

Linseed oil is traditionally applied on cricket bats. As Linseed oil is not water-resistant, it is not suitable for finishing wooden objects that are used outdoors.

In fact, most DIYers use Linseed only as a component of other finishes, e.g. mixed with turpentine to produce a wood conditioner. It is also often combined with paints and stains.

You can find more details on Wikipedia.

Boiled Linseed Oil

Find and compare Boiled Linseed oil on Amazon.

In a Nutshell:

Appearance

- Uniform and soft finish

- Slightly glossy look

Usual drying time

- One or a few days drying time

- Takes longer to fully cure

Characteristics

- Can be toxic (refer to the instructions on the can)

- Hard-wearing finish

Components

- Raw linseed oil

- Heated linseed oil (heated for a few days at several hundred centigrade, the so-called stand oil)*

- Additives to enhance the drying time

*not all ‘boiled linseed oil’-labeled products contain stand oil – it is often replaced with less expensive additives (to retain similar characteristics

Typical use (Examples)

- Interior wood

- Used for terracotta and stone

- Porous surfaces

- Not to be used for oak

Price

Check current prices for Boiled Linseed oils on Amazon.

Boiled Linseed oil produces a hard-wearing finish. It is supposed to offset the biggest disadvantages of Linseed oil: it is easier to apply and it dries faster. However, it is not very weather- and water-resistant either.

Boiled Linseed oil in its original form consists of raw linseed oil, heated linseed oil (usually heated for a few days at several hundred centigrade, the so-called stand oil) and additives to enhance the drying time.

However, not all ‘boiled linseed oil’-labeled products contain stand oil which is replaced with less expensive additives to achieve similar characteristics of the final product. While linseed itself is a natural product, the combination with certain additives can make it a toxic finish (refer to the instructions on the can). Be careful when working with Boiled Linseed oil in any case: it can easily ignite, and cloths with oil residues can be quite dangerous in particular.

Read more about boiled linseed oil in our dedicated

article “Boiled Linseed Oil Uses”.

How Does a Finish with Boiled Linseed Oil Look Like?

Boiled Linseed oil gives a wooden surface a uniform and soft finish with a slightly glossy look.

How Long Does Boiled Linseed Oil Take to Dry?

After its application on a work piece, Boiled linseed oil usually dries within one or a few days. Nevertheless, it takes longer until it is fully cured.

How to Apply Boiled Linseed Oil

Be careful when working with boiled linseed oil as it can easily ignite – therefore, clean soaked cloths immediately in clean water!

- Sanding

As a first step, sand the surface with a fine sandpaper. - Preparation

Thin the oil, if necessary, before the application. - Application of the Boiled Linseed oil

Apply the oil with a brush, roller or cloth, working parallel to the grain of the wood. Remove the excess oil after about 10 to 20 minutes. - Application of more coats

Repeat the previous steps after 1-2 days, as often as desired. Consider sanding between coats, if necessary. - Final sanding

Use a fine sandpaper (fine-grit >= 220) or steel wool to polish the surface.

What Is Boiled Linseed Oil Used for?

As a hard-wearing finish, it is often used for wooden furniture or wooden floors inside the house, in particular if the surface of the wood is porous. It can also be used for terracotta and stone.

Boiled linseed oil is not suitable for finishing oak though. As it can be toxic, it shouldn’t be used around the kitchen or for objects with food contact either.

Read more in our article on Boiled Linseed Oil Uses.

Danish Oil vs. Teak Oil vs. Hemp Oil vs. Tung Oil vs. Boiled Linseed Oil – Which One Should You Choose?

All of these oils are popular in their respective areas of application. All of them are polymerizing (i.e. hard-drying) oils.

What does Polymerization mean?

This term refers to chemical process where monomers (single molecules) are bond together and form a polymer. For wood oils, this happens in the process of curing, i.e. the finish transforms into a hard coat by polymerization when being exposed to oxygen (you can find the source and more details on popularwoodworking.com).

How to Find the Right Oil for Your Project

When choosing an oil for your project, you might consider the following criteria and questions:

Appearance: Do you prefer a matt, satin, glossy or shiny finish? Do you want a certain hue?

Drying time: Is the drying time a relevant criterion for you? Do you have space for the oiled wood to dry, and do you have the time to wait between and repeat re-coating over a timespan of several days or weeks?

Characteristics: Do you require certain characteristics, e.g. water-resistance or an oil being non-toxic for use around the kitchen?

In the below table, you will find a comparison of these aspects for each type of oil that we have discussed in this article. Click on the picture to enlarge it or download it.

Check out our section on oil and wood finishes where you will find more detailed articles and comparisons of these oils. If you are still unsure whether oil is the right finish for your project, you will also find these 10 tips for choosing the right wood finish as well as our overview of Poly, Varnish, and Shellac useful to explore the alternatives.

I love your wood oil cheat sheet!

Mike

Thanks for table with finishing oils.

You’re welcome!